Packaging materials for Foods

Practical Action

Laminated films

Lamination (bonding together) of two or more films improves the appearance, barrier properties

or mechanical strength of a package. Some examples of laminated films are shown in Table 2.

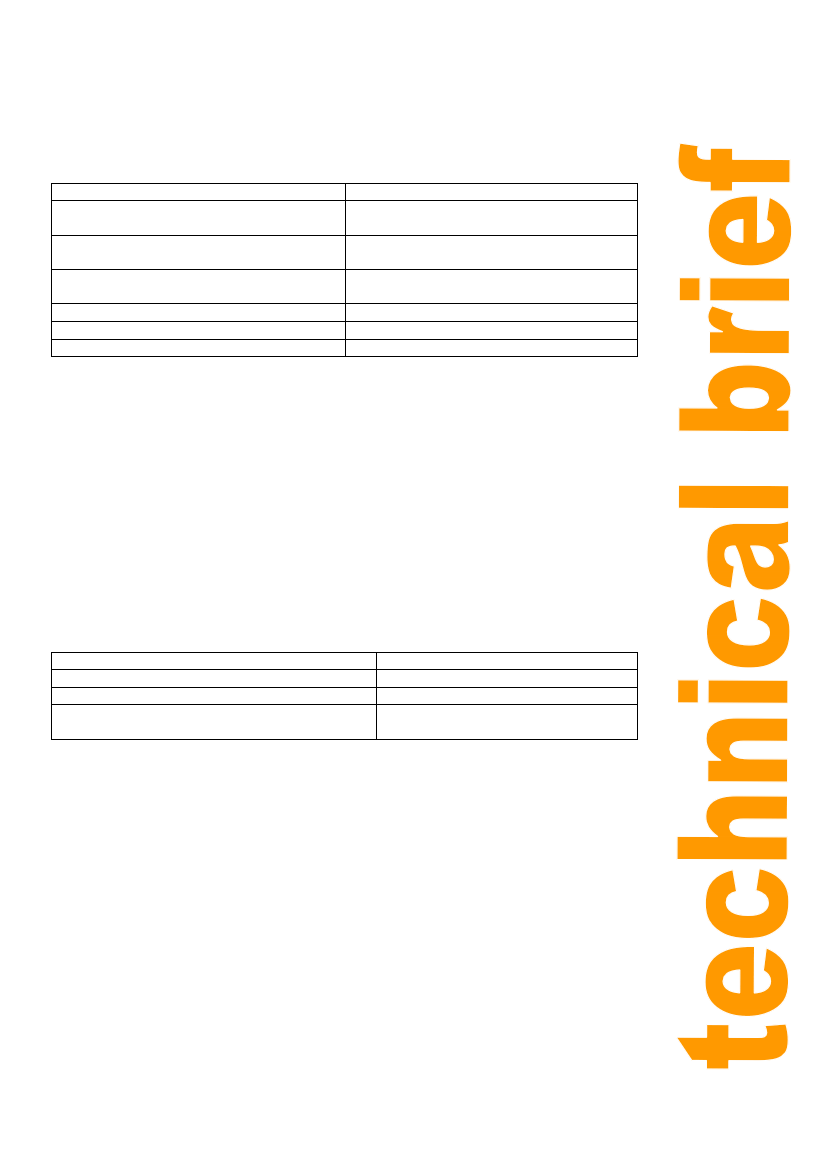

Table 2: Selected laminated films used for food packaging

Laminated film

Typical food applications

Polyvinylidene chloride coated polypropylene Crisps, snackfoods, confectionery, ice cream,

(2 layers)

biscuits, chocolate

Polyvinylidene chloride coated polypropylene- Bakery products, cheeses, confectionery,

polyethylene

dried fruit, frozen vegetables

Cellulose-polyethylene-cellulose

Pies, crusty bread, bacon, coffee, cooked

meats, cheeses

Cellulose acetate-paper-foil-polyethylene

Dried soups

Metallised polyester-polyethylene

Coffee, dried milk

Polyethylene-aluminium-paper

Dried soup, dried vegetables, chocolate

Coextruded films

Coextrusion is the simultaneous extrusion of two or more layers of different polymers to make a

film. Coextruded films have three main advantages over other types of film: they have very high

barrier properties, similar to laminates but produced at a lower cost; they are thinner than

laminates and are therefore easier to use on filling equipment; and the layers do not separate.

There are three main groups of polymers that are coextruded:

Low-density and high-density polyethylene, and polypropylene.

Polystyrene and acrylonitrile-butadiene-styrene.

Polyvinyl chloride.

Typically a three-layer coextrusion has an outside layer that has a high gloss and printability, a

middle bulk layer which provides stiffness and strength, and an inner layer which is suitable for

heat sealing. They are used, for example, for confectionery, snackfoods, cereals and dried foods.

Thicker coextrusions (75 - 3000 m) are formed into pots, tubs or trays (Table 3).

Table 3: Selected applications of coextruded plastic films

Coextruded film

High impact polystyrene-PET

Polystyrene- polystyrene-PvDC- polystyrene

Polystyrene- polystyrene-PvDC-polyethylene

Typical food applications

Margarine, butter tubs

Juice and milk bottles

Tubs for butter, cheese, margarine,

bottles for coffee, mayonnaise, sauces.

Rigid and semi-rigid plastic containers

There is a wide range of plastic bottles, pots, jars, trays and tubs made from single or coextruded

plastics that are increasingly used for processed foods, when they are available in developing

countries. The main advantages, compared with glass and metal, are as follows:

Lower weight, resulting in savings of up to 40% in transport and distribution costs. Cups,

tubs and trays are tapered (a wider rim than base) for more compact stacking for transport

and storage.

Lower production costs using less energy.

Tough, unbreakable and easy to seal.

Very good barrier properties.

Precisely moulded into a wider range of shapes than glass or metal containers.

Can be coloured for consumer appeal and to give UV-light protection to foods. However,

they are not re-usable, are less rigid than glass or metal for stacking and cannot be heated

to the same high temperatures as glass and metal. They are used for example as:

Cups or tubs for margarine, processed meats, cheese, spreads, yoghurt, peanut butter, dried

foods or ice cream and desserts (high-nitrile resin copolymers or high-impact polystyrene

and acrylonitrile butadiene styrene).

Trays for meat products and chocolates, tubs for margarine or jams, and (polyvinyl chloride)

- good oil resistance and low gas permeability.

7